Look after equipment to make it last and ensure it runs efficiently

Foodservice equipment prices will continue to rise for the foreseeable future, and the new equipment will take longer to arrive. Those are the stark warnings of FEA (Foodservice Equipment Association) in the face of what it is calling a ‘perfect storm of challenges.’

“Recent media coverage of the dramatic rise in the price for nickel have underlined the problems,” says Keith warren, chief executive of FEA. “Stainless steel prices had already risen by between 17 and 33% recently. The price is going to rise further with the dramatic increases in the cost of the alloys used in stainless steel for foodservice appliances, such as nickel and molybdenum. The cost of nickel rose from $25,000 a tonne to $100,000 a tonne in just two days! Meanwhile energy and employment costs are increasing, along with inflation. And while the availability of components is more stable and is improving, they are still on extended order times.

“Sadly, these are global issues – there is nowhere else to go to get equipment.”

Alongside price pressures and component delays, manufacturers and importers are having to deal with staff shortages and the complications of Brexit.

FEA advises against purchasing equipment that’s not up to spec simply because it’s available. “It won’t meet the need and, in a short time, it’ll need replacing,” says Warren. “Worst case scenario, an under-specced appliance could compromise safety of staff and customers.”

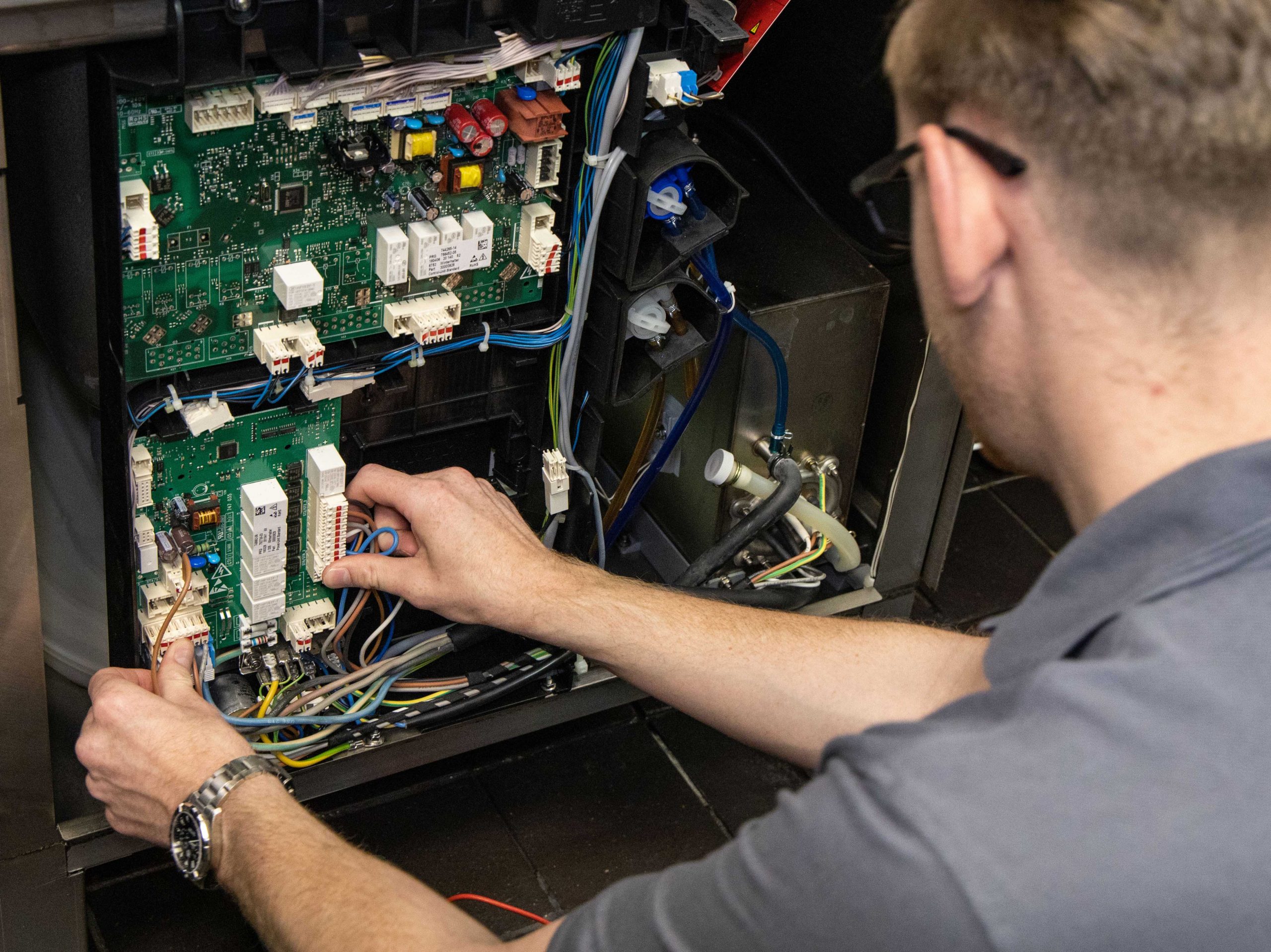

So what’s the answer? FEA says it’s more imperative than ever that new equipment orders are placed as quickly as possible and that they look after the equipment they already have, in order to maximise its service life and ensure it is running as efficiently as possible. The two elements to that are staff training, so that appliances are maintained day-to-day, and regular servicing by qualified engineers.

Most suppliers and manufacturers will offer staff training, and many have online resources, such as ‘how to’ videos, that staff can easily access to learn about specific maintenance and cleaning tasks. To find a reliable service company FEA says it’s important to use a certified organisation, such as a member of the FEA Accredited Service Provider Scheme.